HAND MADE PAPER FROM

INVASIVE MASSACHUSETTS PLANTS

papers and paper art, made from locally foraged plant fibers

paper connected to community

White Leaf: locally grown, small batch paper

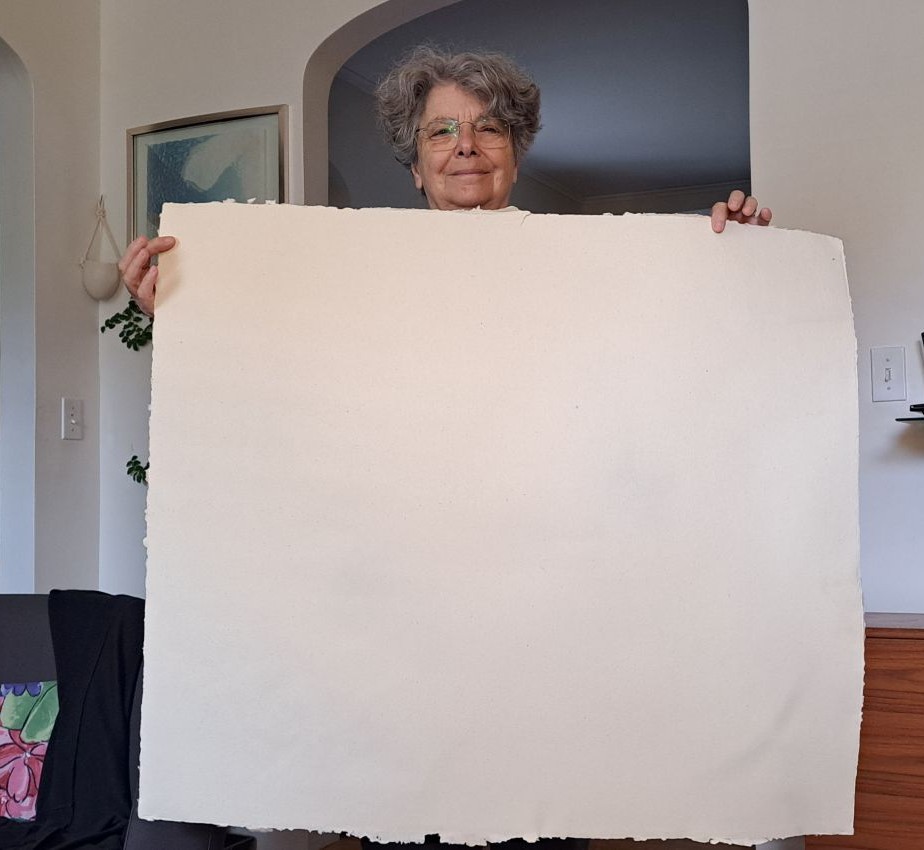

each sheet is unique in all the world

I collect plants for pulp fiber as close to home as I can, limiting myself to invasive plants on the prohibited plant list or to agricultural byproducts, like corn husks

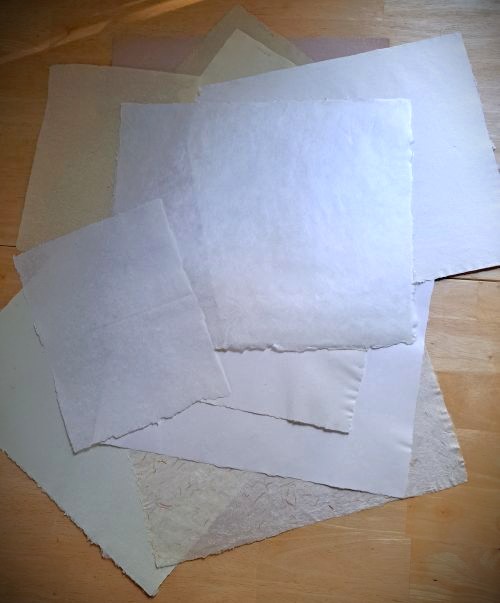

- Beautiful - Tactile, smooth but fibrous, rattly paper in shades of white, cream, tan and green.

- Slow - Made by an ancient, hand process of dozens of steps. Every step includes the human hand, and many steps include only the human hand.

- Enduring - This paper can last for centuries.

My papers are made of the fibers of:

Locally Invasive Plants

leaves or stems

Chinese Silvergrasss (Miscanthus sinensis)

Common Reed (Phragmites australis)

Japanese Knotweed (Fallopia japonica)

Yellow Flag Iris (Iris pseudacorus)

Locally Invasive Plants

inner bark

White Mulberry (Morus Alba)

Bittersweet (Celastrus orbiculatus)

Native or Agricultural Plants

Corn husks (Zea mays)

Hemp (Cannabis sativa)

Milkweed floss (Asclepias syriaca)

how the paper is made

I make White Leaves.

My paper is built from the leaves and stems of the plants in my garden, on my street, in my neighborhood.

Friends and neighbors give me leaves from their gardens, and point me to stands of wild plants for harvest.

The leaves or stems pass through a process that can last a year and a half or more, and comprises dozens of steps. When the paper finally emerges, in very small batches, it is precious.

Handmade

My paper is made in an artisan's studio, using an ancient, low tech process of dozens of steps. Every step includes the human hand, and many steps include only the human hand.

Pulp

Paper is made from cellulose, a fiber found in all plants.The plants I forage are cut, chopped, and trimmed. Then the usable parts are boiled in a water solution of high pH., dissolving everything but the cellulose.The extracted cellulose is reduced to a pulp in a handmade machine called a Hollander Beater.

Sheet formation

That pulp is floated in a vat of water, and a screen is passed through the vat from the bottom to the top to collect the pulp in a smooth layer.

Now something happens,

which only happens in papermaking ---

the individual tiny cellulose fibers form a chemical bond that rarely occurs in nature, turning the mass of fibers into a sheet of paper.

technical information

Chemical Information

Ecological Information

- My pulps are all made with municipal drinking water, from the City of Northampton, MA, U.S.A.

- The collected plant material is cooked with washing soda, and rinsed by machine, after being neutralized with household vinegar.

- Some of my pulps are made without a beater, by action of chlorine bleach. The bleach is rinsed out before sheet formation. Most of my pulps are bleached after beating, and then formed into paper or pigmented.

- My paper has calcium carbonate added to the pulp as a buffer while it is beaten, and starch added for sizing after beating. These two chemicals make the paper archival, (for which there is no legal standard) more or less. If you need the paper to meet legal standards for permanent paper, this may not.

- No laboratory testing has been done on my pulps or papers. (If you do any, I would love to know the results!)

Ecological Information

- My pulp and papers are made in an artisan workshop, with tools as low tech as I can manage.

- Plants are harvested by hand with knives or sickles, and transported by van. Some are harvested less than 2 miles from the studio, some one block down the street; some harvested on my property, some about 5 miles away. Trimmed parts of invasive plants are composted in areas where the plants already grow. All other waste plant materials are composted for garden use. Non invasive plants are harvested around the neighborhood, except for corn. That comes from a farm in the next county over. Maybe 12 miles away.

- Cooking of plants is done on high efficiency induction cookers, in stainless steel pots.

- All of my electricity is generated by a utility using only renewable wind and solar.This website uses mostly solar energy for its servers.

- Soak and fermentation water is poured on the garden.

- Cooking liquor is sent to the water treatment plant via the municipal sewer system, as is used bleach. My volume of use of the household chemicals of washing soda, vinegar and bleach is roughly equal to a household washing diapers for an infant.

- Here in New England, we usually have plentiful water. Still, I am mindful of conservation, and annually use an amount roughly equal to one adult's shower per day. I have consistently and successfully worked to lower my water use, and I reduce overall production in drought years.